Ang linya nga adunay yano ug makatarunganon nga istruktura, taas nga katukma, sayon nga operasyon ug pagdesinyo sa tawo labi nga nahiuyon sa moderno nga panagsama. Kaylap nga gigamit sa parmasyutiko, adlaw-adlaw nga kemikal, pagkaon ug espesyal nga industriya. Kini ang sulundon nga aparato alang sa taas nga viscous liquid ug pagpuno nga adunay daghang lana. Ang linya nga linya mahimong mag-link sa cap feeder ug capping machine nga pagpuno sa capping line. Uban sa dagway sa sayon nga pag-adjust ug dali nga paglimpyo.

Paglaraw sa Produkto:

1. Adopting piston filling, with high filling precision & easy to disassemble & maintain. There are gravity-type filling, overflowing-filling, weighing-type filling & pump type filling as option for different packages & materials.

2. With humanized design & linear bottle-enter-exit, easy & quick to adjust whole system to meet different bottles production.

3. Filling volume can be adjusted directly via touch screen;

4. Filling speed is easy to control, no bottle no filling. With auto liquid supply system to meet continuous filling & anti-drip filling nozzles to ensure no dripping.

5. Filling is designed with one-button washing function, & can meet CIP online washing if required.

6. Multifunctional capping system is suitable for various threaded caps, like flip caps, spray pump caps, & 3/4-circle caps etc, easy to adjust to meet different bottles, capping force is adjustable, no damage to bottles & caps.

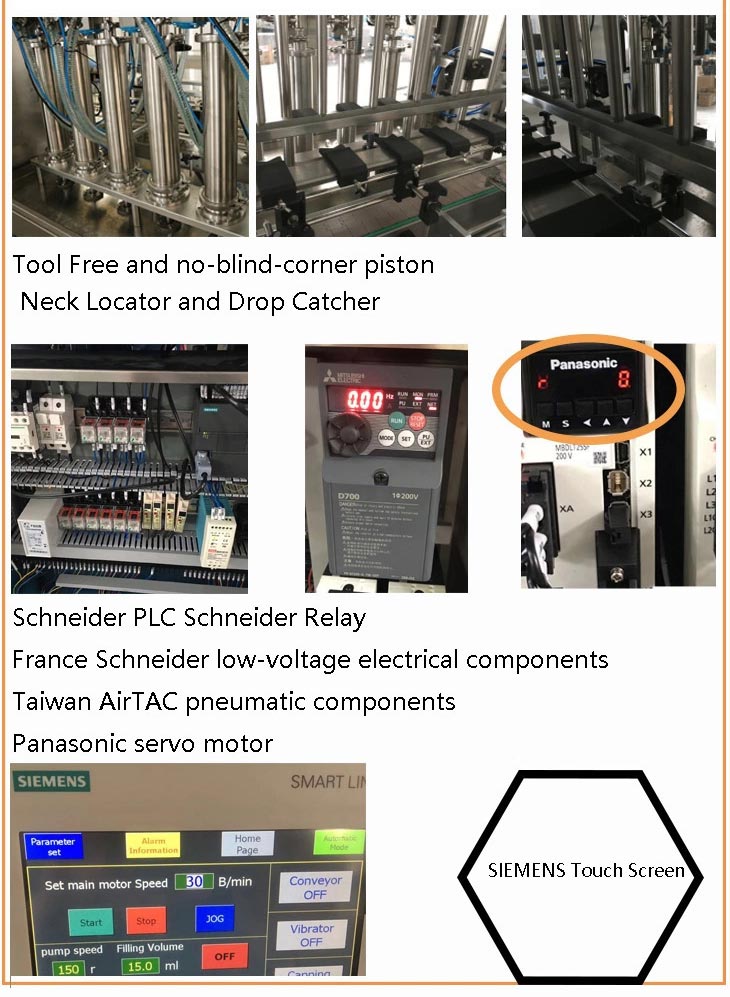

7. With PLC, touch screen to operate, auto counting & with formula saving.

8. All moving parts or electrical, or pneumatic parts are world-famous brands, which ensures the stable & durable running.

9. Mainly made from top-quality stainless steel, all steel parts contacting liquid are stainless steel 316, delicate & durable.

10. Can be customized to the anti-corrosion filling capping line.

11. Mahimo nga gidisenyo ug gihimo nga istrikto base sa mga sukdanan sa CE.

Main Technical Parameters:

| Filling scope | 100-1000ml | 300-3000ml | 500-5000ml |

| Pagpuno nozzle | 8-nozzle | ||

| Capperchoose | Multifunctional capper/ High speed capper | ||

| Cap Diameter | 22-55mm | ||

| Kapasidad | 30-60bpm | ||

| Pagpuno sa sayup | ±0.5%(maximum filling volume) | ||

| Gahum | 220V/380V 50/60HZ2.2KW | ||

| Suitable Bottle | 50-330mm | ||

| Dimension(H x L x H) | 5900x800x1900mm | ||

| Gross Weight | 420kg | ||

Pagputos ug Pagpadala

Packaging:

Ang tanan nga mga makina gitipigan sa standard nga export nga kahoy nga karton (semiautomatic filling machine)

Shipping:

1) Small machines will be shipped by express (DHL, EMS, FedEx ,TNTand so on) or By Air Port.

2) Mga mabug-at nga makina nga ipadala sa dagat.

3) Leading time: 1-3 working days ( semiautomatic filling machine )

Payment:

Ang LC, T / T, Western Union, magamit ang Money Gram

Ang among mga Serbisyo

1) Prompt reply: We will answer your enquiry within 12 hours

2) Warranty time: 1 ka tuig

3) Installation and use guide: We can offer theinstruction manual and video of the machine for you

4) After-sales service: We will follow up our customers all the time after selling out the machine. Please let us know if you meet any question about the machine.

5) Accessories: We supplythespareparts with competitive price if you need.

6) Factory and selling team: We have factory in Guangdong and we have experienced selling team which can communicate in English well. Welcome to visit us at any time.